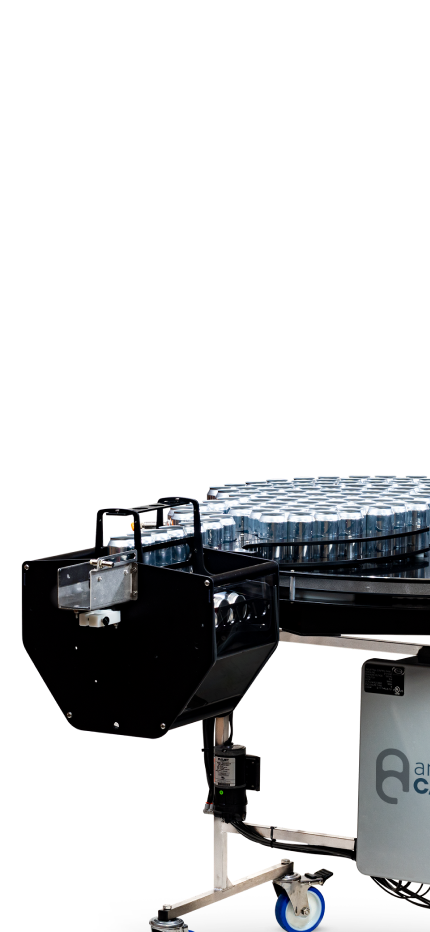

the RT-212 depalletizers are absolute game-changers. These mobile machines effortlessly navigate client facilities daily, proving their durability and reliability. Quick changeovers save me and money, eliminating the need for various twist rinses. The rotating rinse feature, coupled with a lightweight design, offers the benefits of larger depalletizers in a smaller footprint.

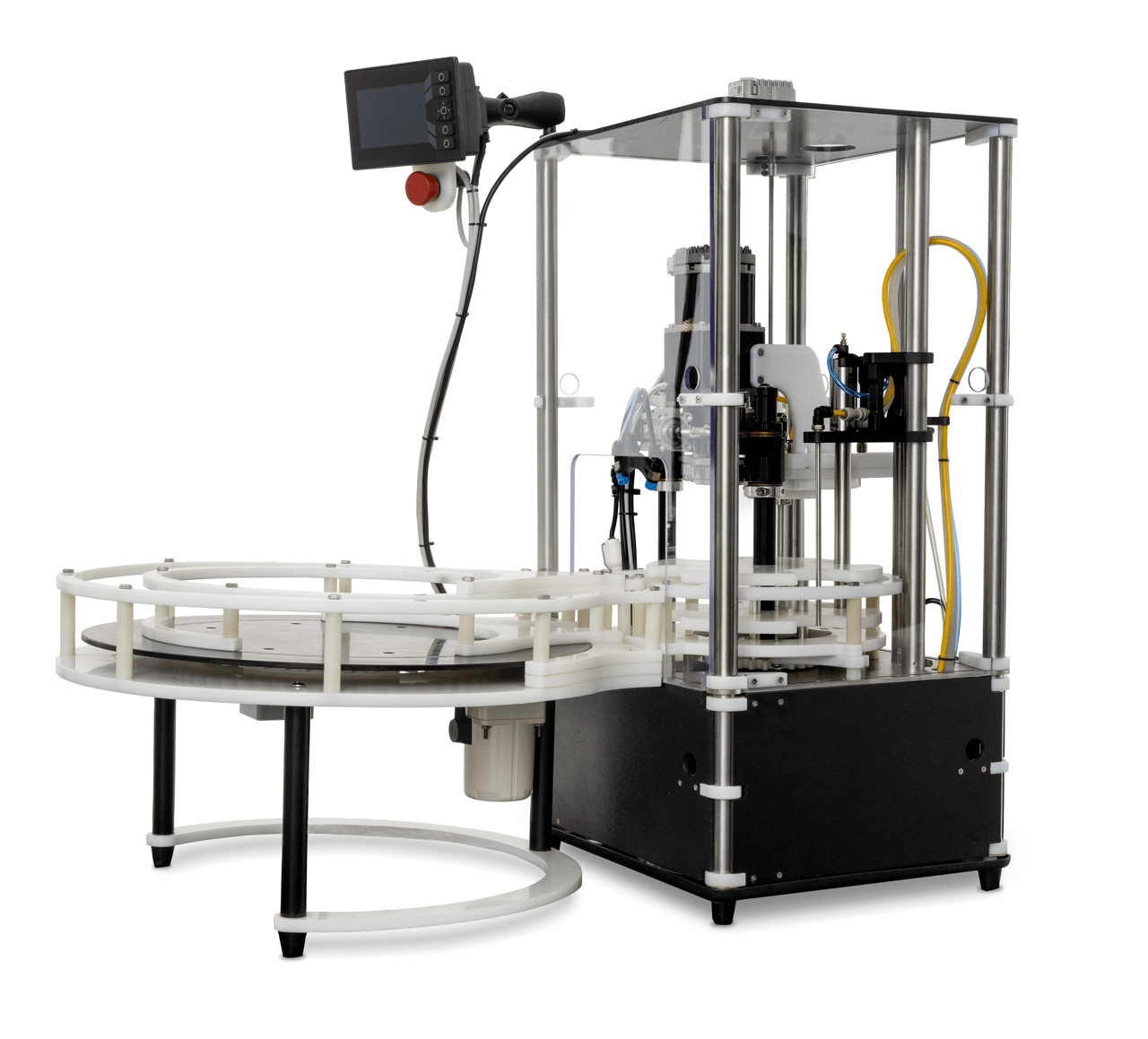

Comprised of a counter-rotating tabletop and flip-rinse cage, the RT-212 is built to constantly convey and rinse cans. It is more compact and cost-effective than small depalletizers and whale-tail systems – ideal for lines that are running 10-60 cans per minute and tight on space, or requiring a mobile setup. With the RT-212, every can gets a great start. Sensors communicate with the infeed to only send cans as needed, preventing damage during a stall. Additionally, the starwheel sends cans at constant speed over the print head guaranteeing consistent date-coding.

Features

- 212 can capacity accumulation table

- Integrated mount for inkjet printers

- Integrated pre-rinse

- Compact 56” x 48” operating footprint

- Mobile-friendly (casters) or stationary frame

- Foldable design for easy, out-of use, storage

- No change parts required to adapt to different fill volumes

- No dedicated water or air supply required

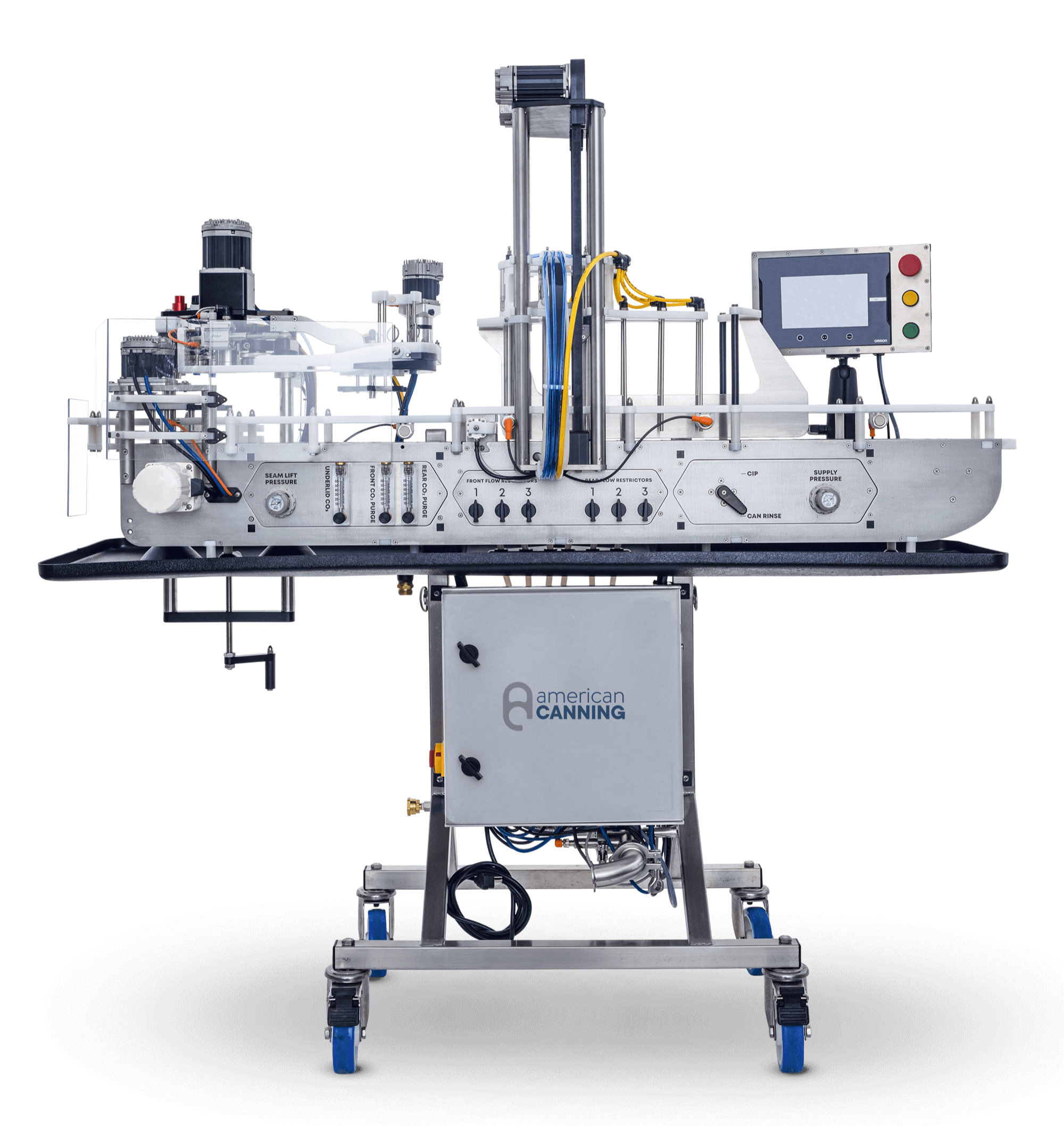

Crafted in The USA

Every machine we offer is designed and manufactured with pride in Austin, Texas, showcasing the best of American ingenuity and quality. Opt for American Canning and support excellence in local manufacturing, guaranteeing high-performance equipment for your beverage needs.