Whether it’s your first day canning product or you’ve been canning for years, it is always helpful to review everything you need before the start of your canning day. Working with Kevin Rogers, our resident canning guru, here is a Canning Day Checklist to ensure you have the most efficient and productive run possible.

First we’ll start with how you can prepare in advance, then we walk through the must-haves, and finally we’ll take you through a checklist of actions to take during each part of the day.

At the end of this checklist we talk with Kevin to learn best practices and extra tips about canning.

Weeks Prior

Prepare Supplies

Well before your canning day, you need to ensure you have all of the supplies that you’ll need to complete a canning run. Not having adequate supplies in any of these categories can bring your entire day to a screeching halt. Here are the key supplies to consider.

- Aluminum cans

- Brand Labels (if you are using PSLs)

- Can ends/lids

- Secondary packaging (4- or 6-pack can handles or corrugate boxes)

- Case trays

- Pallets

- Plastic wrap

- Pallet Labels

- Ink and make-up for your date coder

Work with your supplier(s) to make sure you are ordering products early enough in advance to have items in all categories. It is best not to schedule a packaging run until all supplies are in hand and/or their arrival date is known.

Day of the Canning Run

Before you start your canning day, you’ll need to make sure you have adequate staffing, all necessary tools, quality control supplies, and cleaning/clean-in-place (CIP) items.

Coordinate Staffing

There are few things worse for your product or staff morale, than having an understaffed canning day. You need to make sure you have enough staff available to complete the job.

Depending on the scope and speed of your canning line you may need 1 to 3 operators for an efficient canning run. A single operator is typically fine for a one-head filler running up to 12 cans per minute (cpm). Once you are filling 20-30+ cpm, then at least two operators are needed. The main operator can manage filling and infeed, while another staff member focuses on off-packing and palletizing the finished product.

Higher throughout at 30-60+ cpm typically requires at least three staff members: the main operator on filling with additional support both at infeed and off packing. Consider, you may be operating additional equipment to deal with this volume such as an in-line label applicator. The more equipment involved, the more staff you’ll need.

If your current staffing requirements exceed these recommendations, it may be time to explore more efficient canning line equipment.

Because there is no prior agreed-upon plan for volume, there is no way for suppliers to know how much the buyer will need at any given time. This leads to extended lead times and potential delays if the manufacturer, or specific plant, is operating at or near full capacity.

However, the benefit of spot sales is the on-demand nature of the order. If you are just getting started, you are still market testing packaging formats, or if you simply have no idea what your packaging needs will be beyond a couple of months, the spot market may make the most sense for your business. If you know (at least the basics of) your annual supply needs and have a good idea of monthly projections, supply agreements will be in your favor.

Organize Tools

Machines often require minor adjustments throughout the day. The longer it takes to resolve issues, the longer the product sits in a machine and warms up. Avoid wasting time searching for tools you need once there’s a problem. Instead, gather tools beforehand and put them in an easy-to-access location.

Calibrate Seam Check Equipment

Checking seam quality is required before and during every packaging run. Make sure your seam measuring equipment is calibrated and ready for your initial seam checks.

Gather Cleaning and CIP Supplies

Cleaning and sanitizing your equipment is a crucial step at the beginning and end of each packaging run. For this, you’ll need supplies at the ready:

- Non-caustic cleaner, such as Cell-R-Master

- No-rinse sanitizer, such as PAA (peracetic acid)

- A neutral foaming cleaner for washing down the exterior of your machines at the end of a run

Canning Day : Pre-flight Checklist

- Clean equipment - run cleaner and sanitizer through all product lines

- Gather supplies - organize all packaging supplies and tools so that you don’t have to stop the run to refill supplies)

- Verify product condition* - test if the carbonation level is in the right range for your product and if the temperature is correct

- Check seams - test a few cans by seaming the lid to the can and then measure the seam to make sure it’s within spec. If not, adjust accordingly.

- Start your canning run - it’s time to get things going

*Properly conditioned product should land within a certain range of carbonation and temperature for an optimal canning run, particularly if being packaged on an atmospheric filler. The maximum product carbonation level at 33°F is 2.8 volumes CO2, while the maximum product temperature at 2.5 volumes CO is 35°F. Always take the final CO2 reading right before you start your packaging run.

Canning Day : Start

- Pressurize tank - connect your CO2 line to the holding tank and set it to 15 PSI

- Open fill heads - do this before the product line

- Open product line - liquid will start to flow to the fill heads

- Test cycles with product - this can take several rounds to dial your product and machine in, especially if you don’t run the machines very often

- Start packaging - start filling cans

Canning Day : Ongoing

- Maintain infeed - keep loading a steady supply of empty cans to be filled

- Offpack filled cans - box or apply handles if necessary

- Stack into trays and palletize

Repeat these steps until you reach your production goals for the day.

Canning Day : Close

- Close product line at the tank

- Gather cleaners

- Clean the production lines via a CIP process

- Wash down/clean the machine exterior

- Clean and organize packaging area

- Put away and organize supplies

- CAllow machine to fully dry - disconnect all product lines

- Store machine in well-ventilated area

Q&A with Kevin Rogers, Resident Canning Expert at ACM

What’s the first thing a company should do to prepare for canning day?

The first thing is making sure they have all of the packaging supplies they need either on hand or ordered at least a couple weeks ahead.

What are the biggest challenges to canning efficiently?

Having a properly conditioned product. Make sure that the product is carbonated to the correct level for the canning line that you are using.

How do you test for proper product conditioning?

Brewers test their product using a Zahm. Connect the Zahm to the tank and run some product through that equipment. That takes the temperature and pressure inside that vessel. It tells you the level of carbonation - the higher the carbonation is the higher the pressure on the Zahm.

If it’s not enough then you have to add more CO2, which, depending on how much more you need, could take between one hour and one day. If there’s too much you can open a pressure relief valve on the tank, which reduces the CO2.

So does that mean it would be better to over-carbonate a product at first since it’s easier to release pressure?

No, definitely not.

Even though adding carbonation takes more time, it compromises a product far less than removing carbonation from the liquid. When you are removing CO2 then you could be compromising the final product. A lot of work went into creating the product with the exact right carbonation for the taste and aromatics. Removing carbonation from the product itself can remove flavor and aromatics, causing the product quality to drop.

What’s something that is often overlooked as part of a canning process that shouldn’t be?

Properly cleaning machines at the end of the run. The most important thing you can do at the end is making sure that your machines are fully cleaned, dried, and stored properly.

If not, there’s a build up of dried product residue on the machine which causes mechanical issues. Also, mold is a potential problem from a sanitation standpoint. Cleaning and allowing the machine to fully dry prevents product residue build up and mold issues.

Then, make sure to store the machine in a well-ventilated area so that the moisture has the opportunity to evaporate off. Don’t pile boxes or supplies on top of it when you store it away.

What are some misconceptions regarding a canning day?

The most common misconceptions are that the machines are plug and play. There will be some manipulation that you have to do to dial in the product at the beginning of your run. There’s some manipulation that you have to do to control the flow of the liquid into that can. Controlling the foam is important as well, if you get too much then you will underfill the can.

There’s a certain amount of skill development when you’re new to packaging. As with anything, it takes time but you’ll get better at it with practice. Those who do canning runs every day get into a consistent rhythm pretty quickly.

But if you’re canning once a month then it will involve more time to dial in. I recommend that anyone who cans once a month practice first with water just to make sure the mechanical elements of the machine are working right. That way you don’t have to start with your product and then stop once you encounter a mechanical issue.

How do you troubleshoot when something goes wrong so it doesn’t derail your day?

Having all the tools that you need for minor machine adjustments on hand and ready to go helps you fix things quickly. The product that was running through the machine when it was stopped will be warming up as you’re fixing a problem so anything you can do to speed up routine adjustments is vital.

What should someone do if there is a major machine problem while canning?

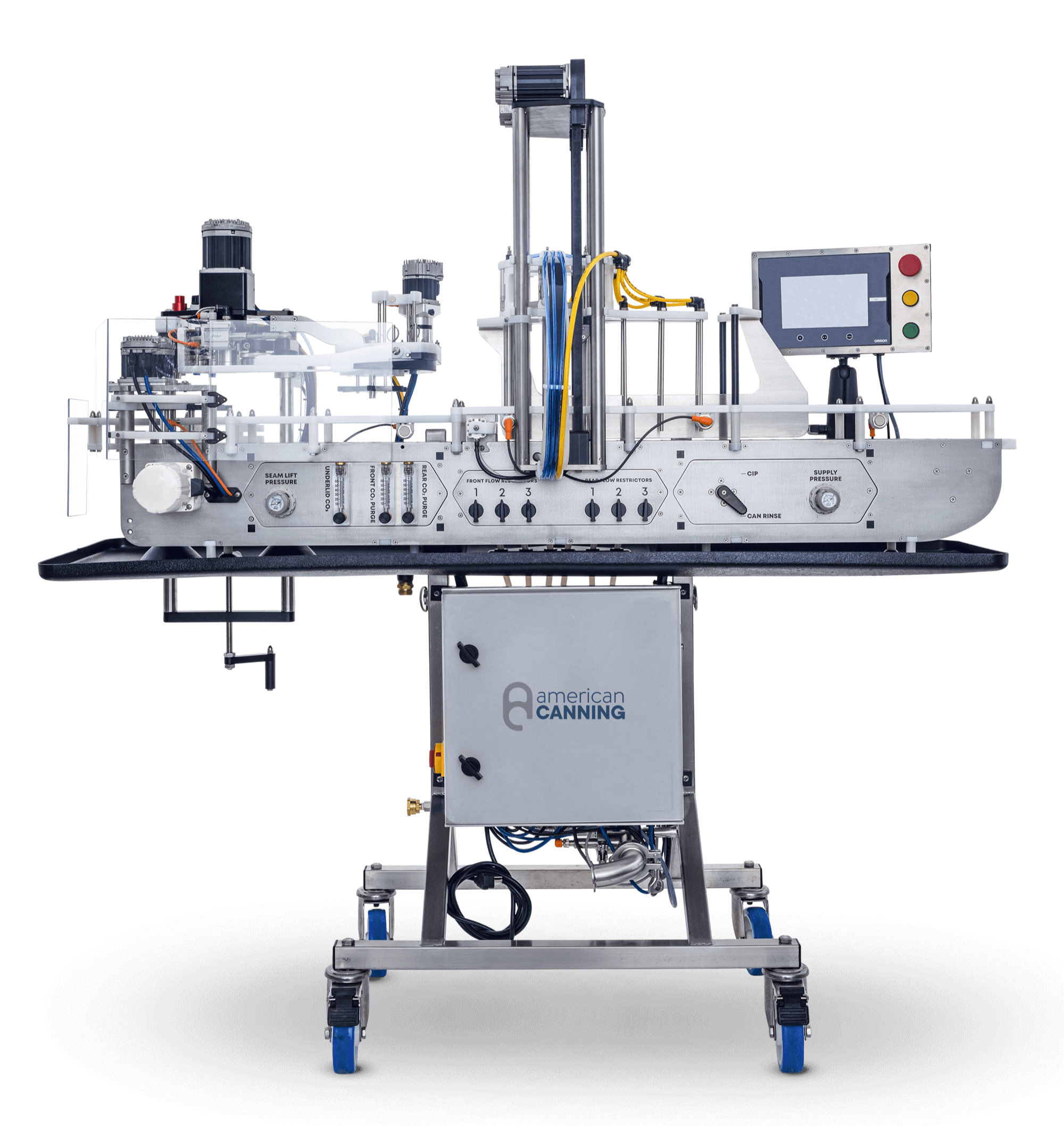

The very first thing to do if they encounter a major issue is to call the machine manufacturer. Speaking for American Canning, most of the time we can get users back up and running as long as they call us first. Sometimes people dig themselves into a bigger hole by trying to fix the problem themselves.

While troubleshooting, close off your product line, then hook up a keg of water to the machine to save money while you troubleshoot the issue.

What are some other things to look out for to avoid issues?

Ensure that your incoming CO2 supply is full or that you have enough to make it through the run, especially if you’re brand new to using a canning line. You need an adequate air compressor for the specs of the canning line.

People often order an inadequate air compressor to save money and then the performance of the machine is less than ideal. This could cause mechanical issues or just slow down the process.